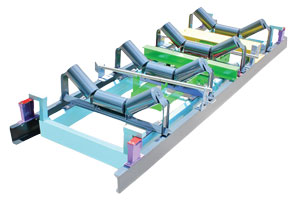

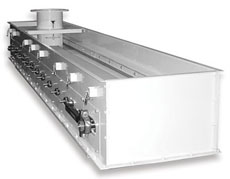

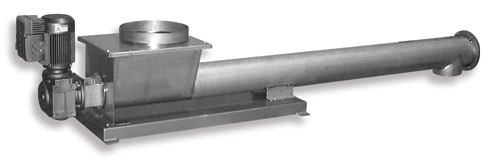

“Better-Weigh®” Batch/Continuous Weigh Feeders are designed to provide feeding in either batch or continuous mode depending upon the arrangement of the feeder’s control electronics. In batch mode, the batch controller is used to control the fast (bulk) and slow (dribble) speeds of the feeder. Accuracies of ±0.5% can be easily achieved in 2 lb. or less batches, and ±0.25% with 3 lb. or greater batches with time spans of 30 to 90 seconds. In continuous mode, the feeder’s electronic controller is used to constantly monitor loss-ofweight of material per time in order to maintain a continuous loss-of-weight with an accuracy of ±0.25% to 0.50%.

“Better-Weigh®” Batch/Continuous Weigh Feeders are designed to provide feeding in either batch or continuous mode depending upon the arrangement of the feeder’s control electronics. In batch mode, the batch controller is used to control the fast (bulk) and slow (dribble) speeds of the feeder. Accuracies of ±0.5% can be easily achieved in 2 lb. or less batches, and ±0.25% with 3 lb. or greater batches with time spans of 30 to 90 seconds. In continuous mode, the feeder’s electronic controller is used to constantly monitor loss-ofweight of material per time in order to maintain a continuous loss-of-weight with an accuracy of ±0.25% to 0.50%.

Features/Benefits

- Accuracy: +/– 0.25% to 0.50%

- Features: Platform or level balance scales, sealed tactile keyboard, 7 digit numerical keypad, automatic manual batching, 2 or 5 cu. ft. hopper. Sanitary construction available.

- All metal contact parts are available in a choice of carbon steel, epoxy coated carbon steel, 304 stainless steel or 316 stainless steel. Carbon steel exterior primed and painted blue enamel. Stainless steel units provided with 2B mill finish.

- Drive Motor HP varies depending upon the material and feed requirements.

Operating Characteristics

- Handles powders, pellets, flakes, and other dry materials where it is necessary to determine actual feed rates on a loss-of-weight basis.

Model BWP/L “Better Weigh”® Batch Feeder

| Model | Feed Rate Max (cu ft/hr) | “L” | “A” | “OD” | HP |

|---|---|---|---|---|---|

| BWP/L-3/4 | 1 | 8″ | 2″ | 1″ | 3/4 |

| BWP/L-1 | 3 | 8″ | 2 3/4″ | 1 1/2″ | 3/4 |

| BWP/L-1 1/2 | 8 | 8″ | 2 3/4″ | 2″ | 3/4 |

| BWP/L-2 | 20 | 12″ | 3″ | 2 1/2″ | 3/4 |

| BWP/L-3 | 60 | 12″ | 3 1/4″ | 3 1/2″ | 1 |

| BWP/L-4 | 175 | 14″ | 3 3/4″ | 4 1/2″ | 1 |

| BWP/L-6 | 550 | 21″ | 4 3/4″ | 6 5/8″ | 1 |

Metalfab “Better-Weigh®” Feeder Controls are available with a “Gain in Weight” mode for applications where a product is being fed into a scale system such as a container sitting on a floor/bench scale or weigh hopper on load cells. In this mode, the controller can verify the zero setting between weighments, auto-tare the weight of a container, verify the container is in position by referencing the container weight setting, or a band value plus or minus to confirm an empty container is in place prior to start of feeding.

A “Loss-in-Weight” mode can be provided for applications where the feeding device is on load cells or a scale system of some type. This mode is used when one or more products need to feed into a process simultaneously, allowing all feeders to dispense product at the same time.

A “Continuous Weighing” mode is provided to continually feed product at a preset rate on a per-second, per-minute, or per-hour basis. Refilling of the feeder can be automatic through input of minimum and maximum weight values to the controller.

Features/Benefits

- Automatic batching or continuous feed rate control

- Automatic feed rate optimization for fast and slow speed settings as well as dribble point determination are performed automatically

- Automatic pre-act (material in suspension compensation) adjustment

- Automatic JOG feature to bring batch into tolerance

- Analog output to represent weight or feed rate as standard

- Additional Analog outputs available for weight or feed rate as needed

- Batch history (or rate logging) to archive the previous 200 records. Rate logging can be set for time intervals as needed.

- System alarm output

- Security includes two levels of password protection

- Tolerance checking with different parameters for under and over tolerance settings

- Remote start and stop contacts provided

- Can “Abort” or “Resume” a batch after E-stop

- Standard unit includes 12 outputs and 12 inputs to control equipment. Some are preprogrammed for specific applications.

- Analog input options available for remote entry of batch size or feed rate from remote PLC or DCS

- Communication options include but are not limited to: Ethernet I/P, Device Net, DH Plus, DH-485, DF1 Half, and DF1 Full Duplex

- Please Note: Custom programming can be provided to control additional upstream or downstream equipment as needed.

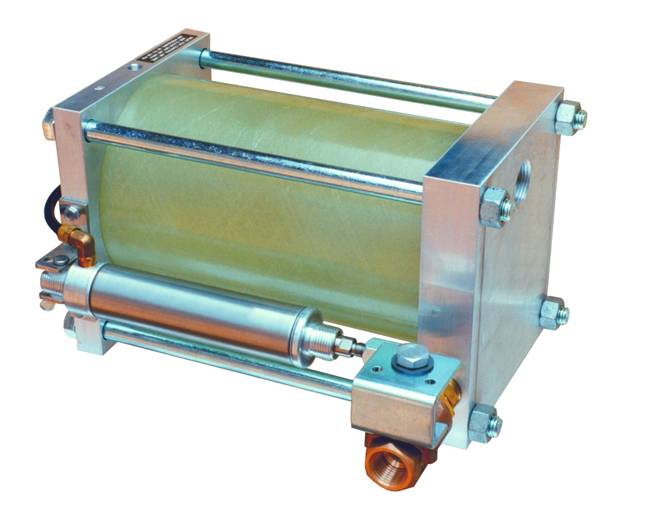

Dimensions

Model BWP/L “Better Weigh”® Batch Feeder Control

Enclosure: NEMA 4X

Display Type: 5.7˝ 16 shades of gray (touch screen)

Visual Display: 4.72˝ x 3.5˝ (119.4 x 88.9 mm) touch screen / 6 -7 segment 0.8˝ digits weight display

Screen Pixels: 320 x 240

Power: 120 VAC @ 2 Amp 1 ph 50/60 Hz (does not include product feeder)

Typical Power Consumption: 0.30 Amp @ 120 VAC (36 W)

Operating Temperature: 32 to 113°F (0 to 45°C)