Eriez Magnetic Plate Magnets are used in the bottom of an inclined chute or suspended above a thin burden of material on a belt conveyor or stainless steel vibratory feeder to remove ferrous contamination. Self cleaning plate magnets, as well as Magnetic Hump, Round Pipe Separator, and Deep Reach Separator designs are also available.

Eriez Permanent Plate Magnets provide dependable and economical solutions to problems associated with tramp iron contamination in processing lines. Plate Magnets installed in chutes, spouts, ducts, pipes, or suspended over conveyors remove tramp iron to help prevent costly shutdowns associated with machinery damage, prevent spark– caused fires and explosions, prevent product contamination and improve product purity.

Features & Benefits:

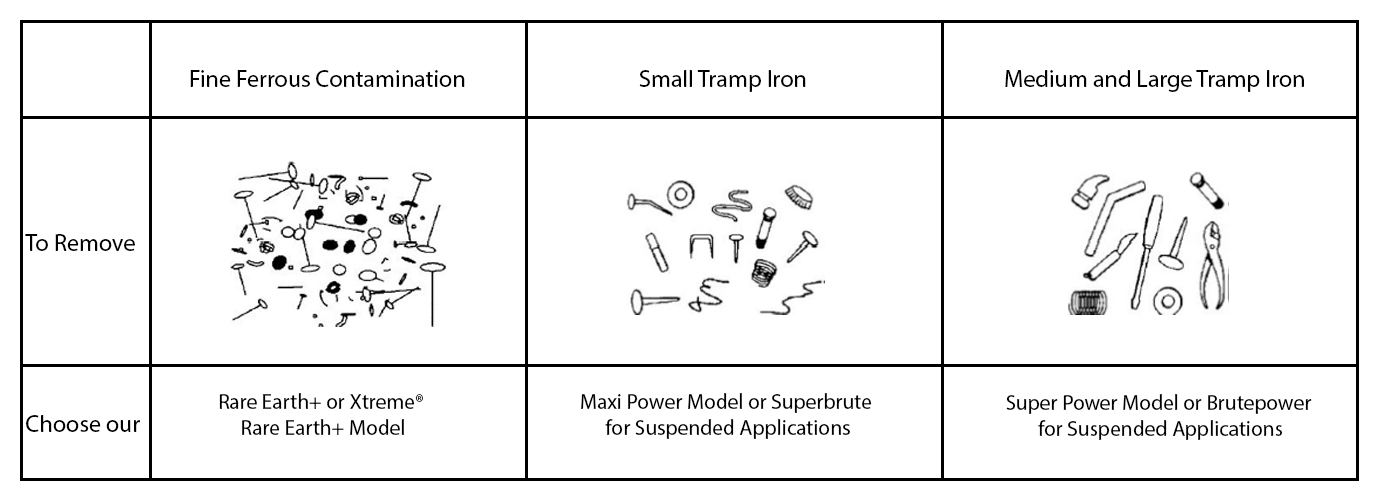

Typical plate magnet installations involve free flowing products cascading down a sloped chute. Use the selection guideline above for thin burdens (up to 5-inches (127 mm)) and slow product flows. Typical installations locate the magnet near the chute entrance to take advantage of the products reduced velocity. For optimum performance, magnets require cleaning at regular intervals. Install them in a readily accessible location.

Since 1976, we’ve helped manufacturers with their filtration, process & material handling needs. From filtering air, gas & liquids to moving, processing & packaging bulk solids – we’ve successfully done it.

Join our newsletter for updates and tips to improve your industrial process.