Van Air is the originator of single tower dryer technology. Our single tower desiccant compressed air dryers prevent moisture in pipelines by suppressing the pressure dew point by 20° F or more from the inlet temperature. Water vapor is removed from the air as it passes through a bed of deliquescent desiccant within the dryer. Our single tower desiccant dryers are adaptable to changing conditions and can be installed indoors or out. They are the most versatile and cost-effective air dryers manufactured today.

Van Air single tower compressed air dryers require minimal maintenance, have no moving parts, and are built to last. All metal surfaces of the vessel interior are primed and coated with polyurethane material. All exterior metal surfaces are protected with an enamel coating. All of this ensures that our single tower air dryers are able to withstand corrosion, chipping, and cracking in the most demanding environments. With a 10 year warranty, we offer the best vessel warranty in the business.

No electricity is needed to operate a Van Air single tower desiccant air dryer. Simply add the appropriate Van Air absorbent desiccant for effective and efficient operation. Typically, a properly sized single tower air dryer only needs to be filled with absorbent desiccant two or three times per year. In addition to the energy savings, operating costs are minimized since desiccant usage is based on actual air flow through the dryer.

The Van Air deliquescent desiccant used in our single tower compressed air dryers is CFC free. It is also non-toxic and non-polluting posing no hazard to groundwater, living organisms or sewage treatment systems as demonstrated through the results of a bioassay test.

With low initial captial investment and operating costs, energy-free and environmentally safe operation, and wide application versatility, our single tower compressed air dryers are the winning choice for maximizing air system efficiency and corporate profits. Contact us to discuss how Van Air compressed air dryers and equipment can provide you with the best value for your money.

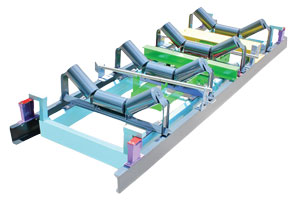

Need a complete skid package with air dryer, aftercooler, and filter?

Consider the Blast Pak or Dry Pak Desiccant Packaged Air Dryer Systems.

| Model | 5 PSIG | 10 PSIG | 15 PSIG | 25 PSIG | 50 PSIG | 75 PSIG | 100 PSIG | 125 PSIG | 150 PSIG | 175 PSIG | 200 PSIG | 250 PSIG |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D-2 | 1.2 | 1.5 | 1.8 | 2.4 | 3.9 | 5.5 | 7 | 8.5 | 10.1 | 11.6 | 13.1 | 16.2 |

| D-4 | 1.7 | 2.2 | 2.6 | 3.5 | 5.6 | 7.8 | 10 | 12.2 | 14.4 | 16.5 | 19 | 23 |

| D-8 | 8.6 | 11 | 13 | 17 | 28 | 39 | 50 | 61 | 72 | 83 | 94 | 115 |

| D-12 | 17 | 22 | 26 | 35 | 56 | 78 | 100 | 122 | 144 | 165 | 187 | 231 |

| D-16 | 27 | 33 | 40 | 54 | 87 | 121 | 155 | 189 | 223 | 256 | 290 | 358 |

| D-20 | 43 | 54 | 65 | 87 | 141 | 196 | 250 | 304 | 359 | 413 | 468 | – |

| D-24 | 64 | 81 | 97 | 130 | 212 | 293 | 375 | 457 | 538 | 620 | 702 | – |

| D-30 | 107 | 135 | 162 | 216 | 353 | 489 | 625 | 761 | 897 | 1034 | 1170 | – |

| D-36 | 146 | 183 | 220 | 294 | 479 | 665 | 850 | 1035 | 1221 | 1406 | – | – |

| D-42 | 215 | 269 | 324 | 433 | 705 | 978 | 1250 | 1522 | 1795 | – | – | – |

| D-48 | 258 | 323 | 388 | 519 | 846 | 1173 | 1500 | 1827 | 2154 | – | – | – |

| D-54 | 344 | 431 | 518 | 692 | 1128 | 1564 | 2000 | 2436 | 2872 | – | – | – |

| D-60 | 429 | 538 | 647 | 865 | 1410 | 1955 | 2500 | 3045 | – | – | – | – |

| D-66 | 515 | 646 | 777 | 1038 | 1692 | 2346 | 3000 | 3654 | – | – | – | – |

| D-72 | 601 | 754 | 906 | 1211 | 1974 | 2737 | 3500 | 4263 | – | – | – | – |

| D-78 | 687 | 861 | 1036 | 1384 | 2256 | 3128 | 4000 | 4872 | – | – | – | – |

| D-84 | 773 | 969 | 1165 | 1558 | 2538 | 3519 | 4500 | 5481 | – | – | – | – |

| D-90 | 945 | 1184 | 1424 | 1904 | 3102 | 4301 | 5500 | 6699 | – | – | – | – |

| D-96 | 1031 | 1292 | 1554 | 2077 | 3384 | 4692 | 6000 | 7308 | – | – | – | – |

| D-102 | 1202 | 1507 | 1813 | 2423 | 3949 | 5474 | 7000 | 8526 | – | – | – | – |

| D-108 | 1288 | 1615 | 1942 | 2596 | 4231 | 5865 | 7500 | 9135 | – | – | – | – |

| D-114 | 1460 | 1830 | 2201 | 2942 | 4795 | 6647 | 8500 | 10,353 | – | – | – | – |

| D-120 | 1632 | 2046 | 2460 | 3288 | 5359 | 7429 | 9500 | 11,571 | – | – | – | – |

| D-126 | 1803 | 2261 | 2719 | 3634 | 5923 | 8211 | 10,500 | 12,789 | – | – | – | – |

| D-132 | 1975 | 2476 | 2978 | 3980 | 6487 | 8993 | 11,500 | 14,007 | – | – | – | – |

| D-138 | 2147 | 2692 | 3237 | 4327 | 7051 | 9776 | 12,500 | 15,224 | – | – | – | – |

| D-144 | 2319 | 2907 | 3496 | 4673 | 7615 | 10,558 | 13,500 | 16,442 | – | – | – | – |

| D-156 | 2748 | 3446 | 4143 | 5538 | 9025 | 12,513 | 16,000 | 19,487 | – | – | – | – |

Locate the column for the minimum operating pressure and read down to the capacity that meets or exceeds your requirement. Next, find the corresponding dryer model group in the left column. From that model group, choose the specific model that meets or exceeds your maximum anticipated operating pressure based on the following model suffixes.

Model | Flow (SCFM) | A | B | C | D | E | F | In / Out Conn. | Filter Hatch | Weight | Dry-O-Lite Fill (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D-2 | 7 | 3.5 | 12.5 | 11.8 | – | – | 1.2 | 1/2″ NPT | Removable | 4 | 2 |

| D-4 | 10 | 4.5 | 28 | 7 | 22.5 | – | 5.1 | 3/4″ NPT | 2″ NPT | 30 | 6 |

| D-8 | 50 | 8.5 | 35 | 9.5 | 28 | – | 5.1 | 3/4″ NPT | 2″ NPT | 60 | 30 |

| D-12 | 100 | 13 | 51 | 14 | 38 | 8.5 | – | 2″ NPT | 4 x 3 | 130 | 130 |

| D-16 | 155 | 16 | 55 | 15.5 | 42 | 13 | – | 2″ NPT | 4 x 3 | 145 | 220 |

| D-20 | 250 | 20 | 56 | 16 | 43 | 16 | – | 2″ NPT | 4 x 6 | 210 | 360 |

| D-24 | 375 | 24 | 59 | 17 | 44 | 16 | – | 2″ NPT | 4 x 6 | 285 | 500 |

| D-30 | 625 | 30 | 64 | 22 | 45 | 24 | – | 3″ NPT | 4 x 6 | 640 | 710 |

| D-36 | 850 | 37 | 70 | 25 | 49 | 24 | – | 3″ FLG | 4 x 6 | 780 | 1130 |

| D-42 | 1250 | 43 | 86 | 16 | – | – | – | 4″ FLG | 12 x 16 | 1275 | 1700 |

| D-48 | 1500 | 49 | 91 | 18.5 | – | – | – | 4″ FLG | 12 x 16 | 2150 | 2300 |

| D-54 | 2000 | 55 | 94 | 18.5 | – | – | – | 4″ FLG | 12 x 16 | 2640 | 2900 |

| D-60 | 2500 | 61 | 97 | 18.5 | – | – | – | 4″ FLG | 12 x 16 | 2700 | 3600 |

| D-66 | 3000 | 67 | 100 | 18.5 | – | – | – | 6″ FLG | 12 x 16 | 3200 | 4400 |

| D-72 | 3500 | 73 | 110 | 18.5 | – | – | – | 6″ FLG | 12 x 16 | 4075 | 6300 |

| D-78 | 4000 | 79 | 115 | 21 | – | – | – | 6″ FLG | 12 x 16 | 4775 | 7400 |

| D-84 | 4500 | 85 | 124 | 21 | – | – | – | 6″ FLG | 12 x 16 | 5700 | 10,000 |

| D-90 | 5500 | 91 | 127 | 21 | – | – | – | 6″ FLG | 12 x 16 | 7200 | 11,000 |

| D-96 | 6000 | 97 | 130 | 21 | – | – | – | 6″ FLG | 12 x 16 | 7800 | 13,000 |

| D-102 | 7000 | 103 | 137 | 25 | – | – | – | 8″ FLG | 12 x 16 | 9000 | 14,000 |

| D-108 | 7500 | 109 | 139 | 24 | – | – | – | 8″ FLG | 12 x 16 | 10,300 | 16,000 |

| D-114 | 8500 | 115 | 142 | 24 | – | – | – | 8″ FLG | 12 x 16 | 12,440 | 18,000 |

| D-120 | 9500 | 121 | 145 | 24 | – | – | – | 8″ FLG | 12 x 16 | 12,900 | 20,000 |

| D-126 | 10,500 | 127 | 148 | 24 | – | – | – | 8″ FLG | 12 x 16 | 15,800 | 22,000 |

| D-132 | 11,500 | 133 | 157 | 24 | – | – | – | 8″ FLG | 12 x 16 | 16,700 | 24,000 |

| D-138 | 12,500 | 140 | 155 | 24 | – | – | – | 10″ FLG | 12 x 16 | 17,800 | 27,000 |

| D-144 | 13,500 | 146 | 158 | 24 | – | – | – | 10″ FLG | 12 x 16 | 18,900 | 29,000 |

| D-156 | 16,000 | 158 | 168 | 28 | – | – | – | 10″ FLG | 12 x 16 | 21,000 | 34,000 |

| Flow (SCFM) based on 100 PSI. Price of dryer does NOT include initial fill of Dry-O-Lite desiccant. Dry-O-Lite desiccant is sold in 50 lb. bags, 50 lb. pails, 506 lb. metal drums and 2000 lb. bulk bags. | |||||||||||