Isolated External Heater

Provides an extra moisture of safety. Easy to service with the heating element outside of the vessels. No overhead clearance required. Distribution of heat throughout the desiccant bed optimizes dryer performance and prolongs desiccant life.

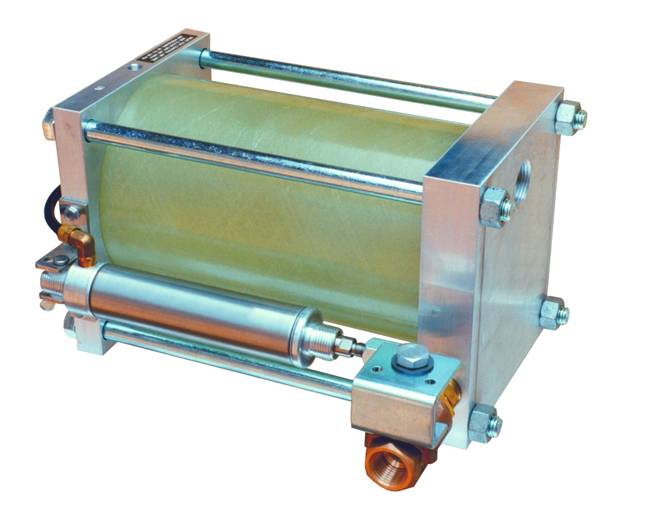

Interlock Logic Valve Control

Patented valve control for the most reliable tower cycling. Each phase of the drying cycle must be completed before the next can begin. Protects against loss of flow or pressure because the offstream tower is fully repressurized before air flow is redirected to it and a tower can only depressurize after the inlet transfer valve is fully seated.

Heatless Back-Up Mode

Switch to this mode and keep the dryer on stream while the heater is being serviced. Prevents loss of production in the event of heater failure or maintenance.

| Model | Flow (SCFM) | Height | Weight | Width | Depth | Heater (KW) | Inlet / Outlet (FLG) | Desiccant Weight per Tower | Total Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HP-150 | 150 | 12 | 82 | 55 | 45 | 2.5 | 1 1/2 | 116 | 902 | ||

| HP-250 | 250 | 20 | 91 | 57 | 45 | 4.5 | 1 /12 | 194 | 1148 | ||

| HP-375 | 375 | 30 | 89 | 60 | 45 | 6.5 | 1 1/2 | 290 | 1480 | ||

| HP-500 | 500 | 40 | 93 | 64 | 45 | 8.5 | 1 1/2 | 388 | 1875 | ||

| HP-650 | 650 | 52 | 101 | 70 | 48 | 11 | 2 1/2 | 513 | 2325 | ||

| HP-800 | 800 | 64 | 93 | 74 | 50 | 14 | 2 1/2 | 625 | 2950 | ||

| HP-1000 | 1000 | 80 | 97 | 75 | 57 | 17 | 2 1/2 | 775 | 3725 | ||

| HP-1250 | 1250 | 100 | 98 | 80 | 53 | 21.5 | 2 1/2 | 963 | 4025 | ||

| HP-1500 | 1500 | 120 | 96 | 90 | 64 | 26 | 3 | 1150 | 4800 | ||

| HP-1750 | 1750 | 140 | 104 | 90 | 64 | 30 | 3 | 1363 | 5475 | ||

| HP-2000 | 2000 | 160 | 114 | 90 | 64 | 34.5 | 3 | 1550 | 6100 | ||

| HP-2500 | 2500 | 200 | 43 | 4 | |||||||

| HP-3000 | 3000 | 240 | 51.5 | 4 | |||||||

| HP-4000 | 4000 | 320 | 69 | 6 | |||||||

| HP-5000 | 5000 | 400 | 86 | 6 | |||||||

| For total desiccant weight, multiply by two. Desiccant shipped installed on HP-150 through HP-500. Desiccant shipped separately on larger units. Due to continuous improvement, dimensions, and specifications may change without notice. Request certified drawing for pre-piping. | |||||||||||

Regenerative dryers must have clean, oil-free inlet air.

Lubricated Compressors – Dryer must be equipped with proper Van Air pre-filters. These filters must be drained and maintained as specified. Desiccant beds should be checked periodically and replaced if contamination has occurred. Failure to do so may result in hazardous operating conditions and will void the warranty. An after-filter should be installed downstream of the dryer to prevent desiccant particle migration.

Non-lubricated Compressors – A particulate or coalescing pre-filter is recommended to prevent pipe scale and dust from fouling the dryer. An after-filter should be installed downstream of the dryer to prevent desiccant particle migration.