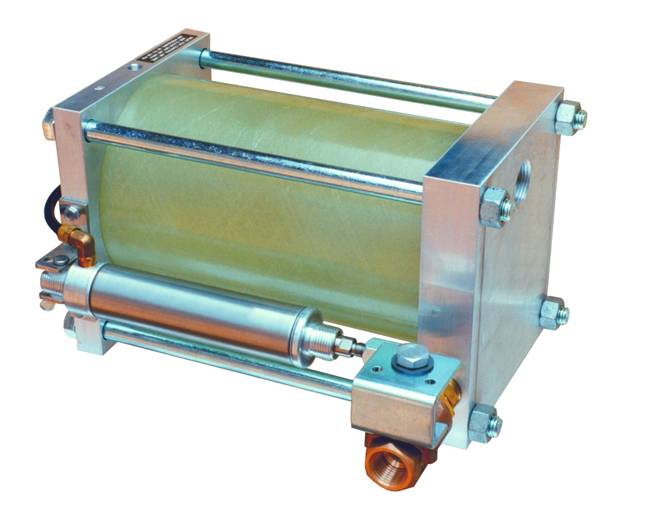

Our rugged F102 Series compressed air filter housings are welded carbon steel, constructed and stamped in accordance with ASME code Section VIII, Div. I code for 250 PSIG at 225° F. All of our filter housings receive a rigorous hydrostatic pressure test of 1.3 times the maximum working pressure.

The exterior of the F102 compressed air filter housing is protected by a coating of primer and air-dried machine enamel. The interior of the housing is protected by alkyd enamel. Both of these coatings help protect against corrosion, chipping and cracking to ensure a long life for the filter housing.

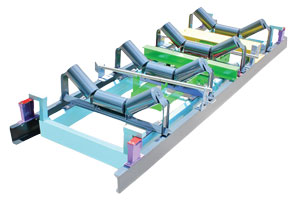

By offering 9 different compressed air filter housings, with flows ranging from 1,500 to 20,000 SCFM at 100 PSIG, Van Air has an F102 Series filter housing to meet a wide range of applications. The filter inlet and outlet connections on the F102 Series housings have port locations that allow for the installation of pressure differential gauges to monitor the status of your filter.

The top-loading feature of the F102 compressed air filter housing allows for the filter element to be easily replaced via an o-ring sealed swing bolt closure. This top-loading feature allows for the filter element to be replaced by one operator and without concerns for ground clearance.

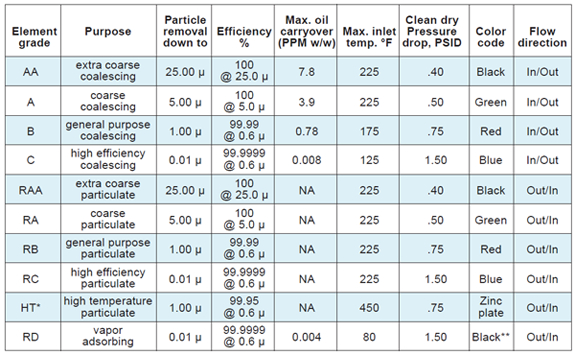

SELECTING A FILTER

To select the appropriate filter, determine the following conditions regarding the filter installation site:

- Maximum flow rate

- Min. and Max. operating pressures

- Operating temperature

- Pipe size

- Degree of filtration desired

- Contaminants to be removed

Next, refer to the Flow Capacities chart below and locate the column with your lowest operating pressure. Then find the flow rate closest to, but greater than, that of your system. Finally, read across to the left-hand column to determine the filter model that will meet your needs.

You will now need to refer to the Filtration Grades chart, also located below. Determine the element grade that meets your needs. Be sure that the maximum inlet temperature listed on the chart is sufficient for your operating conditions.

Refer to the Dimensions and Specifications chart and locate the proper filter model number. Once you have located the model number within the chart, verfiy that the inlet and outlet connections are suitable for your piping. Also make sure that there will be adequate clearance for element replacement.

| Model | 25 (PSIG) | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 |

|---|---|---|---|---|---|---|---|---|---|---|

| F102-1500-* | 520 | 845 | 1175 | 1500 | 1830 | 2155 | 2480 | 2810 | 3135 | 3460 |

| F102-2000-* | 690 | 1130 | 1565 | 2000 | 2435 | 2870 | 3310 | 3745 | 4180 | 4615 |

| F102-3500-* | 1210 | 1975 | 2735 | 3500 | 4265 | 5025 | 5790 | 6550 | 7315 | 8080 |

| F102-5000-* | 1730 | 2820 | 3910 | 5000 | 6090 | 7180 | 8270 | 9360 | 10,450 | 11,540 |

| F102-7500-* | 2595 | 4230 | 5865 | 7500 | 9135 | 10,770 | 12,405 | 14,040 | 15,675 | 17,310 |

| F102-10,000-* | 3460 | 5640 | 7820 | 10,000 | 12,180 | 14,360 | 16,540 | 18,720 | 20,900 | 23,080 |

| F102-12,500-* | 4325 | 7050 | 9775 | 12,500 | 15,225 | 17,950 | 20,675 | 23,400 | 26,125 | 28,850 |

| F102-15,000-* | 5190 | 8460 | 11,730 | 15,000 | 18,270 | 21,540 | 24,810 | 28,080 | 31,350 | 34,620 |

| F102-20,000-* | 6920 | 11,280 | 15,640 | 20,000 | 24,360 | 28,720 | 33,080 | 37,440 | 41,800 | 46,160 |

| Model | Flow (SCFM) | In/Out Conn. (NPT) | Drain Conn. (NPT) | A | B | C | D | E | F | Weight (lbs) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F102-1500-* | 1500 | 3 FLG | 1″ | 18 3/4 | 10 3/4 | 32 | 70 3/4 | 82 | 24 | 309 | |

| F102-2000-* | 2000 | 4 FLG | 1″ | 18 3/4 | 10 3/4 | 33 1/2 | 78 1/2 | 89 1/2 | 30 | 337 | |

| F102-3500-* | 3500 | 6 FLG | 1″ | 24 3/4 | 12 3/4 | 32 | 77 1/2 | 92 | 30 | 420 | |

| F102-5000-* | 5000 | 6 FLG | 1″ | 28 | 16 | 33 1/2 | 78 1/2 | 93 | 30 | 582 | |

| F102-7500-* | 7500 | 8 FLG | 1″ | 32 | 20 | 34 1/2 | 80 1/2 | 98 1/4 | 30 | 823 | |

| F102-10,000-* | 10,000 | 10 FLG | 1″ | 36 | 24 | 35 1/2 | 83 3/4 | 104 1/4 | 30 | 1089 | |

| F102-12,500-* | 12,500 | 10 FLG | 1″ | 36 | 24 | 35 1/2 | 83 3/4 | 104 1/4 | 30 | 1130 | |

| F102-15,000-* | 15,000 | 12 FLG | 1″ | 42 | 30 | 44 1/2 | 94 3/4 | 117 3/4 | 30 | 1771 | |

| F102-20,000-* | 20,000 | 16 FLG | 1″ | 52 | 36 | 46 | 99 1/4 | 126 | 30 | 2428 | |

| Insert approprate filtration grade (-RB) after part number. Flow is based on SCFM at 100 PSIG at 100 F. Weight includes housing and element. Due to continuous improvement, dimensions and specifications may change without notice. Request certified drawings before pre-piping. | |||||||||||