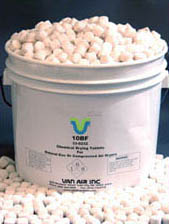

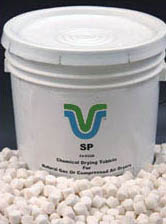

Molecular sieve is a sodium aluminosilicate. It has a fixed pore size according to the material specified, a 4 Angstrom pore size being the most common.

(1 Angstrom – 3.94 x 10-9 inches)

Because of its high comparative cost, it is normally used for special process applications. Pressure dew points to -100°F may be achieved with molecular sieve depending on the dryer design and operating conditions.

| Color and form | Off white / tan bead |

| Bulk Density | 49 lbs. / cu. ft. |

| Surface Area | 3.67 x 106 sq. ft. / lb. |

| Relative Humidity | |

|---|---|

| 100% RH | 23% |

| 90% RH | 22.5% |

| 60% RH | 21% |

| 10% RH | 19% |

| 33-0317 | 5 lb. Pail |

| 33-0249 | 25.b Pail |

| 33-0265 | 50 lb. Bag |

| 33-0250 | 330 lb. Steel Drum |

Uniform retention capacity

Moisture retention (pounds of water adsorbed per pound of desiccant) does not change appreciably if the air or gas is not saturated. It also keeps its moisture retention properties over a wider range of operating temperatures.

Round bead shape

Round shape has high abrasion resistance and results in lower pressure drop than extruded molecular sieve.