Activated alumina is a porous form of aluminum oxide. It has a high surface area which adsorbs vapors without any change in form. Activated aluminas will not soften or disintegrate easily when immersed in water.

Dew points to -40°F and lower may be achieved with activated alumina depending on dryer design and operating conditions.

- The 1/8″ (2-5mm) activated alumina bead is the size most frequently used in regenerative dryers.

- The 3/16″ (4-8mm) activated alumina bead is used when pressure drop and surface area requirements fall between 1/8” and 1/4” material. It is suitable for most systems.

- The 1/4″ (5-10mm) activated alumina bead is used both as a pre-bed material to support large desiccant beds or as a buffer for silica gel beads. Pressure drop is slightly lower than 1/8” (2-5mm) material.

If size is not known or specified, the 1/8” (2-5mm) size is usually satisfactory. However, if activated alumina is used in a regenerative dryer and the desiccant retaining screens cannot be measured, the 1/4” (5-10mm) size should be used as a bed support (6” layer). If at all possible, obtain a sample material and measure it before ordering.

| 1/8″ (2-5mm) | 3/16″ (4-8mm) | 1/4″ (5-10mm) | |

|---|---|---|---|

| Color and Form | White bead | White bead | White bead |

| Bulk Density | 48 lbs./cu. ft. | 48 lbs./cu. ft. | 48 lbs./cu. ft. |

| Crush Strength | 17-30 lbs. | 45-60 lbs. | 50-70 lbs. |

| Surface Area | 1.74 x 166 sq. ft./lb. | 1.65 x 106 sq. ft./lb. | 1.59 x 106 sq. ft./lb. |

| Relative Humidity | |||

|---|---|---|---|

| 100% RH | 42% | 40% | 36% |

| 90% RH | 37.5% | 35% | 32% |

| 60% RH | 21% | 21% | 17.5% |

| 10% RH | 7.5% | 7% | 6% |

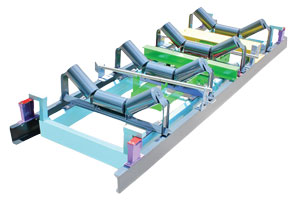

| Model | Flow (SCFM) | Height | Weight | Width | Depth | Blower (HP) | Inlet / Outlet (FLG) | Desiccant Weight per Tower | Total Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HB-350 | 350 | 83 | 63 | 61 | 7.25 | 1.0 | 1 1/2 | 270 | 1740 | ||

| HB-500 | 500 | 90 | 66 | 66 | 10.2 | 2 | 2 1/2 | 388 | 2275 | ||

| HB-900 | 900 | 90 | 74 | 77 | 20 | 7.5 | 2 1/2 | 688 | 3675 | ||

| HB-1300 | 1300 | 98 | 104 | 68 | 27 | 7.5 | 3 | 1013 | 4925 | ||

| HB-2000 | 2000 | 113 | 120 | 76 | 41 | 10 | 3 | 1550 | 6500 | ||

| HB-3000 | 3000 | 122 | 142 | 84 | 60 | 15 | 4 | 2325 | 10,850 | ||

| HB-4000 | 4000 | 133 | 162 | 95 | 79 | 15 | 6 | 3075 | 13,550 | ||

| HB-5000 | 5000 | 122 | 174 | 100 | 98 | 15 | 6 | 3875 | 16,150 | ||

| Due to continuous improvement, dimensions, and specifications may change without notice. Request certified drawing for pre-piping. Contact us for larger models up to 10,000 SCFM or special features. | |||||||||||

Regenerative dryers must have clean, oil-free inlet air.

Lubricated Compressors – Dryer must be equipped with proper Van Air pre-filters. These filters must be drained and maintained as specified. Desiccant beds should be checked periodically and replaced if contamination has occurred. Failure to do so may result in hazardous operating conditions and will void the warranty. An after-filter should be installed downstream of the dryer to prevent desiccant particle migration.

Non-lubricated Compressors – A particulate or coalescing pre-filter is recommended to prevent pipe scale and dust from fouling the dryer. An after-filter should be installed downstream of the dryer to prevent desiccant particle migration.