Magnetic Traps employ the same powerful tube magnet used in Eriez Grate assemblies, but are specifically designed for liquid product flows. The traps are available in a variety of designs and include an inlet port to match the existing pipeline, a magnetic element to collect the tramp metal contamination, and a transition back to the existing pipe. Ceramic and Rare Earth tube magnets are available for removal of tramp metal to fine ferrous particulates.

Eriez’ line of powerful, permanent magnetic Ferrous Traps provide magnetic protection for liquid lines and processing equipment. They preserve product purity by removing small particles of magnetic scale, rust and fine iron contamination.

Protect your flow lines and products with the world’s finest liquid handling magnetic separators. Prevent abrasive wear, prevent pumps from jamming and assure yourself a product free of iron contamination… achieve the iron contamination protection your particular operation requires – whether it be a tiny 1/2–inch (13 mm) pipeline or a huge 30–inch (762 mm) diameter line, Eriez has a magnetic circuit to provide the protection that will serve you best.

All models of Ferrous Traps have a constant powerful magnetic circuit designed to attract and hold iron contamination. Clean, simple designs have no moving parts… powerful, permanent magnetic element will perform well handling materials with temperatures up to 150°F (65°C), with special models available for temperatures to 850°F (454°C).

Xtreme® Traps

The Xtreme® style Rare Earth (RE) separators available from Eriez remove weakly magnetic or very fine iron contaminants. Eriez Rare Earth develops a magnetic field up to 25 times the strength of conventional ceramic magnet material. All models of Eriez trap magnets are available with Xtreme elements.

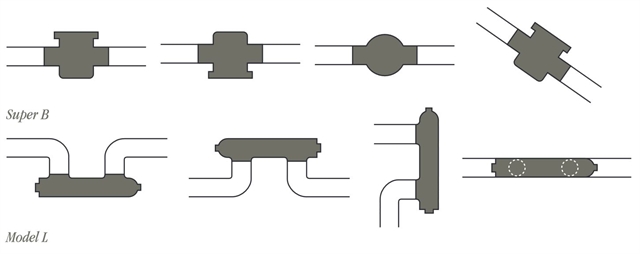

Super B and L types can be installed in most any position. Units can be installed right side up, upside down, on side and on any angle.

For 2″ (51 mm) through 4″ (102 mm) Pipelines

The magnetic element, consisting of a group of magnetic tubes, is arranged to cause the material flow entering the body to impinge against the tubes and filter through the magnetic field, completely covering the open area. This arrangement takes advantage of the material change in direction and the difference in inertia between the unwanted iron and the material carrying it. The magnetic circuit is designed so the entrapped iron will have a tendency to work around and cling to the down–stream side of the tubes. This action prevents iron particles from being washed off by the continuous flow of material.

For 2″ (51 mm) Pipelines

This Ferrous Trap model has been designed to serve as an effective, low–cost, magnetic pipeline trap where operating conditions are not too severe. This unit is of 316 stainless steel construction capable of withstanding pressures up to 150 psi (10.5 kg/sq cm). It is built for 2–inch (51mm) pipelines; standard reducers can be used to adapt it to lines as small as 1/2–inch (13 mm). The powerful magnetic circuit is encased in one stainless steel tube. As a built–in safety factor, any material that might be brushed off by the flow will tend to pass the outlet and accumulate in the pocket at the end of the body.

This unit is the same as the Model L, except it has a brass or optional stainless steel filter sleeve that fits around the magnetic tube, making the unit perform a dual separating operation. Magnetic power from the tube draws and holds fine iron contamination, while the filter element catches and holds nonmagnetic fines, lint, etc. This model is recommended where more than magnetic impurities contaminate a product.

Model U Traps

Model U TrapsFor Difficult-to-Flow Products

The Model U Trap utilizes a Rare Earth magnet circuit to remove fine and weakly magnetic contamination like rust, scale, or screen wire. Model U Traps remove ferrous contamination from difficult–to–flow or chunky products like vegetables, salsa, or meat batters. The special body design of the Model U incorporates a gradually tapered transition that gently directs the product over a smooth magnetic surface. The body design does not incorporate diverters or baffles. This design works well for applications where finger–style traps would plug due to large product size or where delicate products would break if forced against a baffle.

Model T Traps

Model T TrapsFor 6″ (152 mm) through 30″ (762 mm) Pipelines

Reduce damage and maintenance to filters, pumps, refiners and other processing machinery handling paper, chemical slurries and other liquid materials. Rugged welded pipe and reinforced plate and tube construction withstands working pressures up to 75 psi (5.3 kg/sq cm). Model T Traps are primarily for upright installation in horizontal lines, however, they may also be mounted sideways, or in inclined or vertical lines.

Since 1976, we’ve helped manufacturers with their filtration, process & material handling needs. From filtering air, gas & liquids to moving, processing & packaging bulk solids – we’ve successfully done it.

Join our newsletter for updates and tips to improve your industrial process.