FS-CURTIS FS-Connect Aluminum Compressed Air Pipe

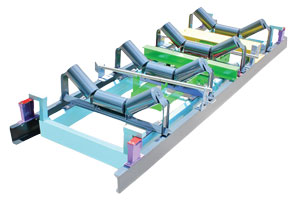

The aluminum FS-Curtis Aluminum Piping System, designed by Parker Transair, revolutionizes the installation and maintenance of compressed air networks, offering a swift, adaptable, and easily adjustable piping solution. Its innovative quick-connect fittings eliminate traditional threading or soldering challenges, streamlining the assembly process. The compressed air piping system’s aluminum construction not only makes the pipes lightweight and manageable, especially in elevated setups but also ensures worker safety during installation. With its design focused on minimizing installation time, maintenance needs, and operational expenses, this FS-Connect compressed air piping system stands out as a highly cost-effective and efficient choice for compressed air distribution.

FS-Connect Aluminum Piping System - 20-21,250 CFM

The FS-Connect Aluminum Piping System features energy efficiency and reduced installation costs, thanks to the push-to-connect technology that allows for immediate system pressurization. The system's components are not only removable and reusable, but also boast a modular design that prevents corrosion and guarantees a leak-free operation. The FS-Connect full bore design optimizes airflow, and the system is available in a wide range of sizes from 1/2" to 6", catering to diverse application needs. Additionally, the materials used in the FS-Connect pipes and fittings are 100% recyclable, underscoring the system's commitment to environmental sustainability. FS-Curtis ensures that all components are silicone-free, further enhancing the system's purity and compatibility with various fluids.

FS-Connect aluminum compressed air pipes are adept at handling a variety of fluids, including different states of compressed air (dry, wet, lubricated), vacuum conditions, and inert gases, making it a versatile choice for numerous industrial applications. For specific fluid requirements beyond these, FS-Curtis encourages direct consultation to ensure compatibility.

The system's durability is evident in its resistance to a wide range of operational challenges, including corrosion, mineral and synthetic compressor oils, aggressive environments, mechanical shocks, oil carryover, and thermal variations. It operates efficiently within a broad temperature range, maintaining a maximum working pressure of up to 232 psi under certain conditions, and is designed to withstand significant vacuum levels. The construction materials, including fiberglass-reinforced polyamide, plated brass, stainless steel, powder-coated aluminum, and nitrile seals, are carefully selected for their durability and performance, ensuring a long-lasting and reliable piping network for all compressed air needs.

FS-Connect Pipe System Benefits

Patented FS-Curtis design

- Energy efficient

- Lower installation costs

- Push-to-connect technology

- Immediate pressurization

- Removable and reusable

- Modular design

- No corrosion

- Leak-free guarantee

- Full bore design

- 1/2″ – 6″ pipe sizes

The material used to manufacture the pipe and fittings are 100% recyclable. The FS-Curtis Aluminum Piping System pipe and fittings are guaranteed silicone free.

SUITABLE FLUIDS

- Compressed air (dry, wet, lubricated)

- Vacuum

- Inert gases

*Please consult us for other fluids.

MAXIMUM WORKING PRESSURE

- 188 psi from -4°F to +140°F

- 232 psi from -4°F to +115°F

*Max. working pressure for 6″ is 188 psi)

RESISTANCE TO:

- Corrosion

- Mineral compressor oils

- Aggressive environments

- Synthetic compressor oils

- Mechanical shocks

- Compressor oil carry over

- Thermal variations

- Ultraviolet (UV)

MATERIALS:

- Fiberglass reinforced polyamide

- Plated brass

- Stainless steel

- Powder-coated aluminum

- Nitrile seals