Dollinger filter elements are available in many styles including air intake filters, panel filters, coalescing filters, oil mist eliminators and specialty filter elements for demanding applications. No filter element can promise to eliminate downtime, but there is one element reliable enough to prevent most causes of unscheduled equipment shutdown due to figure failure or premature plugging.

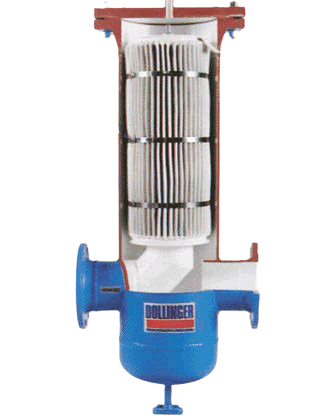

The Dollinger filter element incorporates the efficient radial finned design which provides the largest filtration area for a given filter element size. This increases direct holding capacity, minimizes pressure drop, and results in an extended service. life.

The Dollinger filter element incorporates the efficient radial finned design which provides the largest filtration area for a given filter element size. This increases direct holding capacity, minimizes pressure drop, and results in an extended service. life.

Dollinger filter media utilizes a carbon or stainless steel support structure. The standard Dollinger radial fin filter element design ensures it’s integrity up to a differential pressure of 50 psid. Special designs are available for applications which demand higher differential pressure capabilities. In the event of changing process conditions after installation, it is possible to interchange Dollinger elements to vary the degree of filtration.

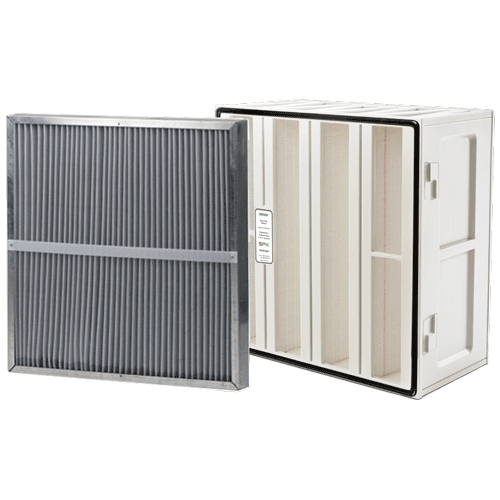

Dollinger panel filters are available in sizes from 24″ x 24″ x 1-1/2″ to 24″ x 24″ x 2″ for the primary stage panel and 24″ x 24″ x 11-1/2″ to 24″ x 24″ x 12″ for the secondary stage. Dollinger panel filters are available with various filter media including Polyester, Washable Synthetic media, Dual Layer Microglass media, and and ASHRAE/EN tested filter media depending on your requirements. Panel filter micron ratings range from 98% of 10 micron to 99.97% of 0.3 micron.

Dollinger panel filters are available in sizes from 24″ x 24″ x 1-1/2″ to 24″ x 24″ x 2″ for the primary stage panel and 24″ x 24″ x 11-1/2″ to 24″ x 24″ x 12″ for the secondary stage. Dollinger panel filters are available with various filter media including Polyester, Washable Synthetic media, Dual Layer Microglass media, and and ASHRAE/EN tested filter media depending on your requirements. Panel filter micron ratings range from 98% of 10 micron to 99.97% of 0.3 micron.

Dollinger Filtration is the only manufacturer of an air intake panel filter rated for 3,000 SCFM. All other panel filters are rated for 2,500 SCFM or lower. The heavy duty frame, pleats, filter media and construction far exceed the quality of any other panel filter on the market.

DOLLINGER RADIAL FIN FILTER ELEMENTS

Whether you require radial finned or panel elements for air, gas or liquid filtration, Dollinger filters and replacement elements ensure maximum protection for your process or equipment.

Since 1976, we’ve helped manufacturers with their filtration, process & material handling needs. From filtering air, gas & liquids to moving, processing & packaging bulk solids – we’ve successfully done it.

Join our newsletter for updates and tips to improve your industrial process.