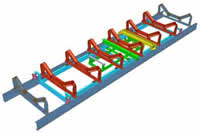

Thayer Scale is pleased to announce that they have received a Certificate of Conformance (CC) covering their Model NAR 4 and 6 idler Belt Scales for applications on conveyor belts of 18 to 96 inches wide, operating at belt speeds between 100 and 1000 ft/min, under loading of 34 to 340 lb/ft, at flow rates of 102 to 10,200 T/hr. The Model NAR family uses the same “graded sensitivity” weighbridge** that has been used by the company for commercial applications for over 30 years. It is particularly well suited for applications involving high belt speeds (>600 fpm) and steep inclines (>12 deg.).

Thayer Scale is pleased to announce that they have received a Certificate of Conformance (CC) covering their Model NAR 4 and 6 idler Belt Scales for applications on conveyor belts of 18 to 96 inches wide, operating at belt speeds between 100 and 1000 ft/min, under loading of 34 to 340 lb/ft, at flow rates of 102 to 10,200 T/hr. The Model NAR family uses the same “graded sensitivity” weighbridge** that has been used by the company for commercial applications for over 30 years. It is particularly well suited for applications involving high belt speeds (>600 fpm) and steep inclines (>12 deg.).

The concluding 6 month “sealed” permanence test was done on May 20, 2005 at Duke Energy’s Buck Power Station, Spencer N.C., handling Coal at 4800 T/hr on a 72 in. wide conveyor running at 700 ft/min at a 15 degree incline. Three material tests were run at that time, with no adjustment made to the zero between each of the tests. Results were: -0.076%, +0.035%, +0.089%, comfortably within the allowable +/-0.25%.

The significance of this performance, of course, can not be put into perspective without taking into account important information regarding the particular conveyor that the scale is installed in, and the differences in environmental conditions between those during the startup tests and those during the concluding tests, 6 months later. Therefore, the following data is provided:

Material: Coal

Seasons: Fall, winter, spring

Temperature, mean value, November 16, 2004 = 58 degrees F

Temperature, mean value, May 20, 2005 = 71 degrees F

Conveyor Length = 240 feet

Conveyor Incline = 15 deg.

Operating Rate = 4800 T/hr

Belt Speed = 700 ft/min

Idler Spacing = 48 inches

Belt Width = 72 inches

Gravity Take-up = 13,000 pounds

Idler Troughing Angle = 35 degrees

We are pleased to have passed our permanence test under these particular conditions, notably the combination of higher levels of Flow Rate, Belt Speed, and Conveyor Inclination, which taken together characterizes the majority of electric Utility applications.

* The “NATIONAL TYPE EVALUATION PROGRAM” (NTEP) is a program of cooperation between the NATIONAL CONFERENCE ON WEIGHTS & MEASURES (NCWM), the NATIONAL INSTITUTE FOR STANDARDS AND TECHNOLOGY (NIST), State Weights & Measures Officials, and the private sector for determining conformance of weighing equipment with the provisions of Handbook 44. NTEP provides the testing procedures for each type of device, oversees its testing, and issues a Certificate of Conformance (CC) upon acceptance. The range of operating parameters that a family of devices covered by a single CC can have is restricted and noted on the certificate.

Handbook 44 is a documented set of requirements for weighing and measuring devices that is used in commerce and law enforcement activities. It is annually reviewed, updated, and published by NIST.

** Hyer, F. S. “The Approach-Retreat Suspension for High Accuracy Belt Weighing”,

Bulk solids handling, Volume 14, Number 4, October/December 1994