First designed for steel mill service to feed flux materials (limestone, mill scale, dolomite, iron ore pellets, fluorspar and coke), the Model “MH” has been subjected to extreme environmental conditions-such as abrasive dusts, corrosive fumes, wide temperature fluctuations and vibrations-without any detrimental effects on performance or accuracy. Its rugged construction coupled with the most advanced electronic controls make it truly THE WORLDS MOST RELIABLE WEIGH FEEDER.

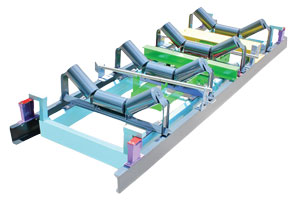

Originally designed for steel mill service, Thayer’s Weigh Belt Model MDH benefits put it into a class by it self. The Model MDH offers an extremely robust design with an intense commitment to quality and attention to detail. With over 50 years of weigh belt experience THAYER produces a weigh belt that is highly accurate, rugged and dependable. THAYER feeders are built to endure the rigors of high capacity feeding and heavy density materials ranging in particles sizes from fines to 6 lumps. The bottom line of using a THAYER Model “MDH” in your process translates into reduced operating downtime, lower overall cost and quick return on your investment.

One of Thayer Scale’s specialty equipment lines is the Model “M” Low-Density Feeder line for weighing bulk materials having densities under 10 lb/ft³. A conventional feeder capable of weighing heavier products (typically 50 lb/ft³ and above) to an accuracy of ½% under limited weekly calibration attention, is likely to achieve no better than 3-4% accuracy when weighing a material having a density of only 5-10 lb/ft³.

One of Thayer Scale’s specialty equipment lines is the Model “M” Low-Density Feeder line for weighing bulk materials having densities under 10 lb/ft³. A conventional feeder capable of weighing heavier products (typically 50 lb/ft³ and above) to an accuracy of ½% under limited weekly calibration attention, is likely to achieve no better than 3-4% accuracy when weighing a material having a density of only 5-10 lb/ft³.

Thee Model MD is an extremely rugged weigh feeder that was originally designed for the harsh environment of the cement industry but can be used in a wide variety of applications. The Model MD is the ideal weigh feeder when medium to high feed rates are required, handling high bulk density and small through large particle size materials. The Model MD can be subjected to extreme environmentalconditions such as abrasive dusts, corrosive fumes, wide temperature fluctuations and vibrations-without any detrimental effects on performance or ac-

Thee Model MD is an extremely rugged weigh feeder that was originally designed for the harsh environment of the cement industry but can be used in a wide variety of applications. The Model MD is the ideal weigh feeder when medium to high feed rates are required, handling high bulk density and small through large particle size materials. The Model MD can be subjected to extreme environmentalconditions such as abrasive dusts, corrosive fumes, wide temperature fluctuations and vibrations-without any detrimental effects on performance or ac-

The Model MDL bridges the gap between standard low capacity and high capacity weigh feeders. Some materials are too abrasive for standard low capacity feeders, lump sizes can be too large or flow rates slightly exceed specified limits, resulting in low accuracy and constant maintenance problems. These applications often can’t be reliably handled by larger, high capacity weigh feeders because the relatively low flow rates fall below specified limits. (for example: feeding 1.5 lumps of coal @ 2 STPH). The Model MDL is as ruggedly built as our capacity weigh feeders, to withstand abrasive materials, but is designed to operate at flow rates just beyond the limits of our low capacity feeders.

The Model MDL bridges the gap between standard low capacity and high capacity weigh feeders. Some materials are too abrasive for standard low capacity feeders, lump sizes can be too large or flow rates slightly exceed specified limits, resulting in low accuracy and constant maintenance problems. These applications often can’t be reliably handled by larger, high capacity weigh feeders because the relatively low flow rates fall below specified limits. (for example: feeding 1.5 lumps of coal @ 2 STPH). The Model MDL is as ruggedly built as our capacity weigh feeders, to withstand abrasive materials, but is designed to operate at flow rates just beyond the limits of our low capacity feeders.

Slack Belt Design for more stable accuracy

Low belt tension means better more stable accuracy. The Thayer weigh belt is driven from the head pulley located at the outlet end of the feeder, rather than the tail pulley located at the inlet end, as in competing designs. This permits lower belt tension during operation for better sensitivity and more stable accuracy. The head pulley is crowned to prevent belt tracking problems and in sheathed in rubber lagging to prevent belt slippage.

Speed Sensor mounted at idling tail pulley

Measures the true speed of the belt via rotation of the idling pulley, not an inferred belt speed based on motor speed. Belt slippage or breakage is immediately detected because the idling pulley stops rotating.

Scale outside material handling area

An idler supporting the belt (the “weigh” idler) transmits the load to the scale, which is located outside the weigh belt enclosure. This design has several benefits. The scale is not prone to damage, is out of the way for cleaning, and is not subject to tare build-up since material cannot fall onto the scale.

High Accuracy, rugged measurement system

100% of the scale’s capacity is used to weigh material. Dead weight of the weigh idler and belt is mass-counterbalanced, thus providing excellent resolution and a high signal to noise ratio. Thayer Scale’s rugged load cell design assures reliable and accurate performance for the life of the weigh feeder.

Automatic Test Weight Calibration

Thayer Scale’s optional automatic test weight mechanism provides the means for applying a precision test weight to allow completely automatic calibration. The calibration sequence can be initiated via the weigh belt instrument keypad or via a contact closure. The need for test chains is eliminated.

Full length adjustable skirt boards

Tapered and flared from the inlet to the discharge to prevent pinching of material between the skirt and the belt. The skirt boards are located inside the belt flanges to provide two barriers to contain material and prevent spillage.

Inlet dimensions custom tailored and computer selected

Ensures uniform withdraw of material from storage. Very careful consideration is given to density, particle size and handling characteristics of your material.

Screw adjustable idler alignment

The idlers adjacent to the weigh idler are mounted on jacks for easy alignment in the field. All idlers are mounted on individual CEMA brackets, permitting removal to either side without major framework disassembly or belt removal.

The Thayer flexure suspension system (Patented) with its linear variable displacement transducer utilizes a series of high tensile strength steel flexures coupled to summing levers to accurately focus force to a tension type load sensor. Force measurement is decoupled from load position and mass counterbalance to accurately measure net material weight.

Design principle:

Load is opposed by tension forces in corner flexures (A). Tension forces in corner flexures produce moments about fulcrum flexures (B). Moment of left hand lever is transferred to right hand lever via equalizing flexure (C). Summed moment in right hand lever is therefore proportional to load irrespective of load position. Moment in right hand lever is opposed by tension in link flexure (D). Tension in link flexures (D) produces a moment in the final lever. Fulcrum flexure (E) transfers force to displacement transducer.

Features:

- Sustained sensitivity without maintenance.

- Cancels horizontal force vectors.

- Nulls out heavy tare loads.

- Immune to off center loading effects.

- 1000% over load capacity

A load sensor cannot distinguish between the “meaningful” force of material weight and other forces. THAYER Weighbelt Feeders are engineered to isolate the load sensor from these other forces, which affect repeatability for highly accurate weighing.

Dead weight is mass counterbalanced, so we can custom-size load sensor range to match application needs. To illustrate the benefit, imagine weighing a small package first on a truck scale and then on a postal scale. Although both are sensitive scales, only the postal scale range matches the application and therefore provides far more accurate results.

Excessive belt tension forces are eliminated by our head pulley drive and low deflection scale. Friction is defeated by using precision rollers instead of slider decks. Torsional forces, caused by off center loading and side forces, are decoupled from the true force transmission by our flexure-based lever system.

Force vector isolation is a Thayer Scale technological advantage. It is one of the best reasons to buy from the weigh feeder experts at Thayer.