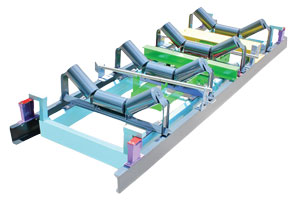

The Thayer Model RF-ALA Belt Scales are Ideal for Biomass Energy Applications. Available with 2,3,4, and 6 idlers, the RF-ALA belt scales were specifically designed for high accuracy (1/10 to 1/2% typical) inventory control and throughput totalization of light scale loading applications such as Biomass, wood chips, saw dust, tobacco and land refuse. The belt scale weigh bridge features exclusive rocking flexure suspension in the approach and approach/retreat configurations. Measurement sensitivity is high while deflection is low. The single load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal -to-noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The Thayer Model RF-ALA Belt Scales are Ideal for Biomass Energy Applications. Available with 2,3,4, and 6 idlers, the RF-ALA belt scales were specifically designed for high accuracy (1/10 to 1/2% typical) inventory control and throughput totalization of light scale loading applications such as Biomass, wood chips, saw dust, tobacco and land refuse. The belt scale weigh bridge features exclusive rocking flexure suspension in the approach and approach/retreat configurations. Measurement sensitivity is high while deflection is low. The single load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal -to-noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

For outdoor conveyor weighing of dusty fines and “stone like” aggregate materials where rugged construction and spill-proof/jam-proof suspension design are the most essential attribute. Working in combination with Thayer Scale’s proven “Rocking Flexure” fulcrums is a completely new “pipestem” single idler suspension system incorporating built-in storage means for its calibration weight (no test chains required). This combination of unique elements provides important advantages for neglected-maintenance operations where ongoing dust build-up and spilled aggregates are known to foul conventional suspension designs. Applications include troughed belt conveyors of 14-48” belt widths (Series 1RF-3A for 14”, 18”, 24”, 30”; Series 1RF-4A for 36”, 42”, 48” belt widths) operating at speeds up to 600 fpm and inclines up to 18 degrees.

For outdoor conveyor weighing of dusty fines and “stone like” aggregate materials where rugged construction and spill-proof/jam-proof suspension design are the most essential attribute. Working in combination with Thayer Scale’s proven “Rocking Flexure” fulcrums is a completely new “pipestem” single idler suspension system incorporating built-in storage means for its calibration weight (no test chains required). This combination of unique elements provides important advantages for neglected-maintenance operations where ongoing dust build-up and spilled aggregates are known to foul conventional suspension designs. Applications include troughed belt conveyors of 14-48” belt widths (Series 1RF-3A for 14”, 18”, 24”, 30”; Series 1RF-4A for 36”, 42”, 48” belt widths) operating at speeds up to 600 fpm and inclines up to 18 degrees.

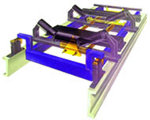

The THAYER 2RF-6A Belt Scale is designed for high accuracy (1/4% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The THAYER 2RF-6A Belt Scale is designed for high accuracy (1/4% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The THAYER 3RF-8A Belt Scale is designed for high accuracy (1/4% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The THAYER 3RF-8A Belt Scale is designed for high accuracy (1/4% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

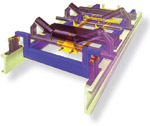

The THAYER 4RF-6AR Belt Scale is designed for high accuracy (1/8% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The THAYER 4RF-6AR Belt Scale is designed for high accuracy (1/8% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

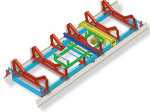

The THAYER 6RF-8AR Belt Scale is designed for high accuracy (1/10% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

The THAYER 6RF-8AR Belt Scale is designed for high accuracy (1/10% typical) inventory control and totalization. The weighbridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, and high sporadic shocks and overloads. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor.

Models NAR 4 and 6 idler NTEP Approved Belt Scales are designed for applications on conveyor belts of 18 to 96 inches wide, operating at belt speeds between 100 and 1000 ft/min, under loading of 34 to 340 lb/ft, at flow rates of 102 to 10,200 T/hr. The Model NAR family uses the same “graded sensitivity” weighbridge that has been used by THAYER for commercial applications for over 30 years. It is particularly well suited for applications involving high belt speeds (>600 fpm) and steep inclines (>12 deg.).

Models NAR 4 and 6 idler NTEP Approved Belt Scales are designed for applications on conveyor belts of 18 to 96 inches wide, operating at belt speeds between 100 and 1000 ft/min, under loading of 34 to 340 lb/ft, at flow rates of 102 to 10,200 T/hr. The Model NAR family uses the same “graded sensitivity” weighbridge that has been used by THAYER for commercial applications for over 30 years. It is particularly well suited for applications involving high belt speeds (>600 fpm) and steep inclines (>12 deg.).

The THAYER “FP” Belt Scale is a unique weighing scale specifically designed to accurately weigh “low density” materials. Weighing deck typically consists of 2 to 6 flat idlers, mounted either horizontally or at an incline of up to 12 degrees, depending on material handled. It can be used in new installations or can be seamlessly integrated into an existing conveyor. Typical application include cereals, snack foods, pet foods, wood fibers, paper waste, tobacco, and textiles (bulk densities ranging from 0.5 to 25 pcf).

The THAYER “FP” Belt Scale is a unique weighing scale specifically designed to accurately weigh “low density” materials. Weighing deck typically consists of 2 to 6 flat idlers, mounted either horizontally or at an incline of up to 12 degrees, depending on material handled. It can be used in new installations or can be seamlessly integrated into an existing conveyor. Typical application include cereals, snack foods, pet foods, wood fibers, paper waste, tobacco, and textiles (bulk densities ranging from 0.5 to 25 pcf).

Since 1976, we’ve helped manufacturers with their filtration, process & material handling needs. From filtering air, gas & liquids to moving, processing & packaging bulk solids – we’ve successfully done it.

Join our newsletter for updates and tips to improve your industrial process.