The Need:

Contaminants at the intake of compressors, blowers and turbines dramatically affect the cost of supplying compressed air. Inefficient intake filtration permits contaminants to corrode, erode and foul internals, effecting a reduction in performance and component service life. Contamination increases repair, maintenance and downtime of rotating equipment. Contaminants not effectively removed by the air intake filter will also migrate downstream in compressed air piping, to system controls, instrumentation, tools and other production processes.

Manufacturing facilities worldwide are experiencing escalating maintenance costs, increasing at an average rate of 10% to 17% annually. These increases are in addition to the related costs associated with downtime, rejects and rework of production process. For “world class” competitiveness, today’s industrial strategies must include management of the high cost of process intake contamination.

The System Prefilter Element

The prefilter is designed to remove the larger size and volume of particulate. The prefilter protects and extends the life of the more efficient final filter which is protecting the equipment internals. Dollinger introduces the newest prefilter media, the VE – 517 Panel which offers extended surface area, now 2″ deep rather than 1 – ½ ” deep providing more than three times higher dirt loading and longer life. The prefilter may be washed by low pressure water hose (

Final Stage Element

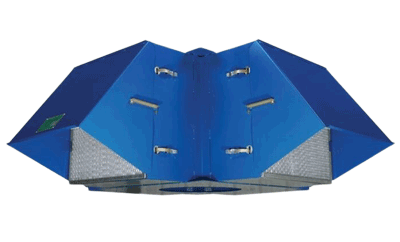

This revolutionary final stage MVP™-502 Multiple Vee Panel design uses a new concept to create eight (8) panels in a “Vee Formation” within a nominal 24″ x 24″ x 11 – ½ ” standard size. A proprietary water resistant microglass media presents a “dual-layer” barrier to particles which penetrate the prefilters. A rugged patented extruded aluminum frame encases the eight (8) panels which are totally sealed in the MVP™.

The features and benefits of this new technology are:

Superior Performance – 99.97% removal of 2 microns and over 90% removal of 0.4 microns protects the performance and life of rotating equipment.

Extended Element Life – More available surface area with the MVP™ design doubles dirt holding capability, extending element life and reducing element replacement costs.

Sizing Flexibility – The MVP™ is capable of flowing up to 3000 SCFM rather than the standard 2500 SCFM. That is a 20% increase in capacity without penalty of added pressure drop. This sizing flexibility allows for a smaller housing and lower first cost.

Since 1976, we’ve helped manufacturers with their filtration, process & material handling needs. From filtering air, gas & liquids to moving, processing & packaging bulk solids – we’ve successfully done it.

Join our newsletter for updates and tips to improve your industrial process.